News

Throwback Thursday: Forge Bank Co Housing Scheme Case Study

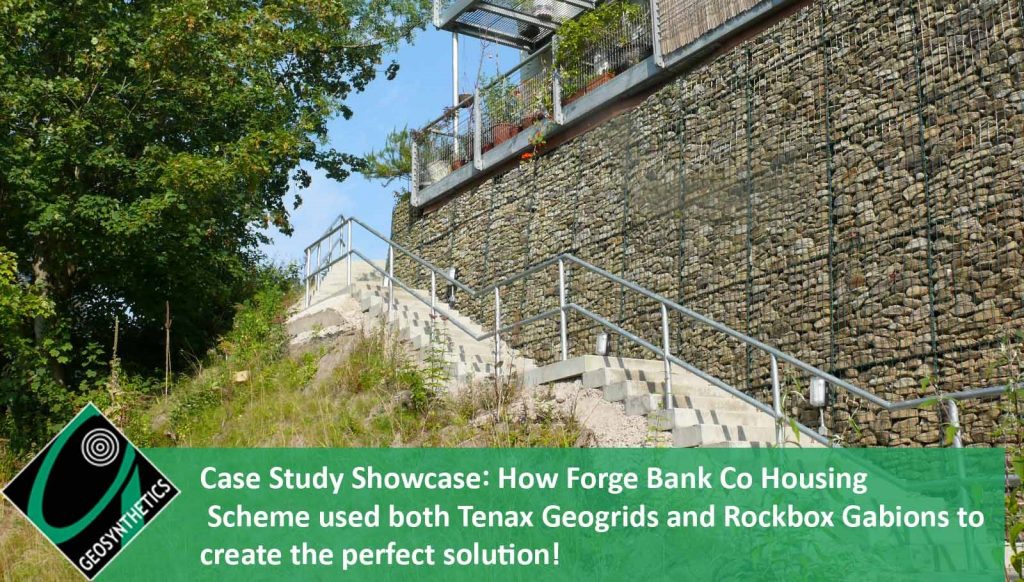

Check out our Forge Bank Co Housing Scheme Case Study below which showcases how Rockbox and Tenax were used together to provide the perfect solution to the sites requirements and maintained the ecological values of the project! If you enjoy the read you can find plenty more case studies showcasing our product range and how our team can support you on our website at http://www.geosyn.co.uk/downloads.

‘‘Geosynthetics limited provided both a solution and on site assistance to enable William Pye Limited to deliver the scheme within both budget and programme.’ – John Rayment – Quantity Surveyor

The Case Study:

Forge Bank Co Housing Scheme is made up of 41 houses designed and built to the highest of eco-friendly standards. Due to it being built on a steep slope, the development required a solution for reinforcing the slope whilst maintaining a low carbon footprint and utilising existing materials.

The solution provided by Geosynthetics Limited combined site won materials with Tenax Geogrids and Rockbox Gabions to create a strong and reliable structure which maintained the ecological values of the project.

The most challenging structure was “Terrace E”. This section of the design called for a 7.5m high reinforced structure. The development also needed to incorporate the column foundations for the 3 bed house above.

Due to the on site soil being a cohesive glacial till it was determined that a reinforced earth wall comprising of Tenax TT uniaxial geogrids would minimise the footprint of the development and more importantly accommodate the column foundations.

Due to the distance between the column foundations to the face of the structure a Tenax LBO biaxial geogrid was introduced for secondary reinforcement to eliminate “Bulging” at the face.

The face of the structure needed to fit in with the natural aesthetics of the site to achieve this a single skin of welded Rockbox units were secured to the face of the wall with a series of mechanical connections.

Duodrain drainage composites were also placed behind the reinforced soil area to alleviate pore pressure. The solution allowed the use of site won soils and dramatically reduced the footprint of the structure whilst providing a finish in keeping with the rest of the development.

Call us on 01455 617139 or email sales@geosyn.co.uk to discuss your site requirements today!